WHAT's Shinwa Belt?

"Shinwa Belt" is a round belt replacement for roller conveyors. Conventionally, roller conveyor belts are driven by round belts, but when the belt breaks during maintenance, the only way to replace it is to remove it from the connection and replace it, which is very troublesome. To replace it, the entire line had to be stopped and a high cost paid to a specialist company. However, if you use Shinwa Belt, this wasteful time and expense is completely unnecessary.

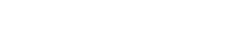

Belt replacement is a one-touch operation

"Shinwa Belt” breaks the conventional wisdom of replacing round belts with a revolutionary method of connecting belts with connectors, making replacement quicker and easier. This minimizes conveyor maintenance time and costs. It can be used

continuously just like a conventional round belt, not just as a temporary fix.

Strong and long-lasting

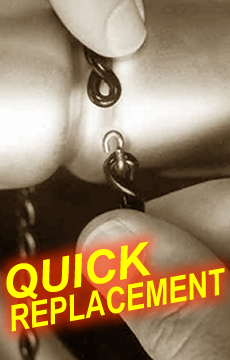

"Shinwa Belt” is a black polyurethane belt that protects against ultraviolet rays and sunlight.

The twisting of the belt body minimizes friction and wear with the rotating rollers. The connecting parts are made of internationally patented stainless steel connectors that are resistant to rust and can withstand harsh use.

Peace of mind and safety

"Shinwa Belt” has a sales track record of over 50 years. In addition to its technology, the company also conducts rigorous strength testing and quality control to maintain the world's highest standards of quality.

Cheaper than round belts

"Shinwa Belt” are priced about the same as general round belts, but when you consider the labor and time required for maintenance, the total cost is much cheaper.

Compatible with almost all manufacturers

The stretch rate is 10% to 20% (normal type), so it is compatible with almost all manufacturers, including Okura Yusoki, Toyo Kanetsu, Maruyasu, Makitec, and others.

ONE-TOUCH

Shinwa belts are connectable (internationally patented stainless steel connectors) , so they can be connected with one touch. They can be used continuously just like conventional round belts.

LOW COST

Compared to conventional round belts and alternative belts, the product price can be kept low, and it is also cost-effective because it eliminates the need to pay expensive replacement fees to specialists and the time spent stopping the line.

HIGH-QUALITY

Our products are of the highest quality and durability in the world, and we provide high-quality products at all times through our unique product management system.

International patent acquired.

Item List

Shinwa Belt

This is a connector-type belt that allows you to replace a broken round belt on the spot with one touch. This is our main product.

Ice Belt

It has low temperature characteristics that allow it to operate in environments as low as -40 degrees Celsius.

Round Belt

This is a normal round belt. Although it takes time to replace, it is stable because it applies a uniform load.

Tiger Belt

This is a long-life round belt that has improved durability compared to conventional round belts.

Product Details

| Shinwa Belt |

Shinwa Belt Hard Type |

Ice Belt | |

| size | 270mm 300mm 330mm |

270mm 300mm 330mm |

Orders can be made in millimeter increments from 180mm to less than 400mm |

| color | Black |

Black |

ivory |

| Cross-sectional area | 5mm | 5mm | 5mm |

| Features | High elongation and tensile strength provide a long bending life, and it is also highly resistant to UV rays and oil. | Ideal for conveyance requiring high load and torque. Features high tensile strength, UV and oil resistance |

It has low temperature properties that allow it to withstand temperatures as low as -40°C, and is compatible with a wide range of chemicals that urethane cannot withstand. |

| Growth rate | 10% - 20% | 5% - 10% | Around 5% |

| Applicable areas | Where bending and rotation are required Where oil components are used Where exposed to ultraviolet light for long periods of time |

Sites where high-load transport oil components are used Sites in adverse environments such as long-term exposure to ultraviolet rays |

For use in refrigerators and freezers |

| Maladjustment | Used in transport locations where high load torque is required | High hardness allows for use in extreme bending and rotation and high friction areas | |

| Usable temperature range | -23℃~66℃ | -23℃~66℃ | -40℃~93.3℃ |

| Hardness "A" Scale ASTM D2240 |

85+/-3 | 92+/-3 | 92+/-3 (ISO868) |

| Ultimate Tensile Strength PSI ASTM D412 |

5,000 | 6,000 | 4,400 (ISO527) |

| Ultimate Elongation % ASTM D412 |

500 | 450 | - |

| Tensile modulus PSI@100% elongation Tensile modulus PSI@300% elongation ASTM D412 |

850 1,870 |

1,660 3,500 |

PSI@5% elongation 400 PSI@10% elongation 600 (ISO527) |

| Tear strength PLI Die”C” ASTM D624 |

500 | 775 | 560 (ISO 34-1) |

Manufacturer's internal test result data (compared to our company)

*Please note that the results may differ from those stated above depending on the intended use, on-site environment, compatibility with the equipment used, and incorrect product selection.

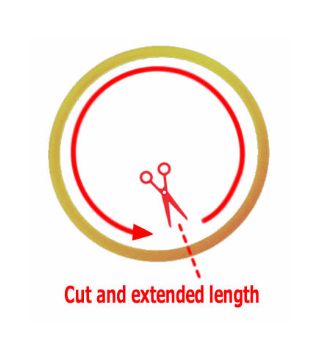

Approximate length to purchase.

Measure and cut the unused Belts.

Length of the total length of unused round belt×0.9

If the round belt total length exact size of the current 330mm

330 × 0.9 = 297mm → fit size 300mm

- Shinwa Belt, is what has been made to conform to a number of conveyor manufacturers.

- Suitability of each conveyor, you'll need to go in your own.

How to use

▲: Quick hook/▼: Hold plate

Unlike conventional round belts, there is no need to remove all the rollers up to the connecting part and replace them by passing them through the drive shaft.

The belt can be replaced simply by removing the rollers where the belt has broken and attaching the Shinwa Belt with one touch, so there is no need to stop the line for long periods of time to perform the work, and maintenance can be performed efficiently in a short time.

About Us

About Us

Shinwa service inc.

351-1, Kamo, Sikama-ku, Himeji-shi, Hyogo, 672-8074, JAPAN

https://www.shinwa-tec.net/

Customer Company

Other Companies...